Maria Septien

Managing Director LATAM

AFIMAC Global

Tony Pelli

Global Practice Director for Security & Resilience

Supply chain and security expert Maria Septien, Director LATAM – AFIMAC Global, and BSI Consulting’s Global Practice Director for Security and Resilience Tony Pelli combine their decades of experience in Latin America (LATAM) operations and global security to break down the essential steps for successful supply chain diversification. Drawing from their previous work together on securing an international tech giant’s LATAM operations, they provide actionable insights on risk evaluation, regional security concerns, and sourcing considerations that organizations should keep in mind.

Investment Over Cost

Too often, organizations view security as a line-item cost rather than an investment in business continuity that can help avoid disruption and loss. This mindset can prove catastrophically short-sighted as security breaches and incidents can inflict losses from which businesses may never fully recover. While companies face ongoing pressure to optimize budgets and reduce expenses, treating security as a prime target for cost-cutting overlooks its fundamental role in protecting core business operations.

Organizations must instead reframe security expenditures as an essential investment that often means the difference between sustainable operations and significant business interruption. Just as businesses wouldn’t consider eliminating insurance or quality control, security should be viewed as a necessary protection for assets, personnel, and operations.

The truth is that a proactive security investment typically costs far less than recovering from a major security incident—if

recovery is even possible.

Moving Beyond “Guns, Guards, and Gates”

While physical security remains important, risks today demand a more sophisticated and integrated strategy.

Security personnel have evolved from being just functional positions focused on physical assets to becoming critical strategic advisors within an organization. The modern security director now serves as a comprehensive risk management consultant, helping different departments understand and address their specific risks, while working with the business units themselves to own these risks. This shift hasn’t been simple and is certainly not over.

The strength of modern security approaches lies in the C-suite’s ability to consider all stakeholders’ perspectives. Effective security requires understanding and coordinating with everyone from operators to facility managers and potentially even community liaison teams. Security now touches every aspect of operations and requires a holistic view that considers immediate and downstream impacts.

While physical security provides a foundation, true resilience comes from understanding where security fits and can benefit overall business continuity, stakeholder relationships, and strategic risk management.

Regional Security—Particularly in Latin America

When diversifying supply chains and operations into LATAM, organizations must recognize that each country, even individual regions within countries, presents distinct operational challenges that call for tailored approaches.

The northern triangle of Central America, for example, presents entirely different challenges than southern cone operations.

Risks can differ even within a single country. In Mexico’s northern states, we see sophisticated organized crime targeting cargo, while in southern Mexico, the concerns might center more around infrastructure reliability and community relations. Each region requires its own security blueprint.

Consider:

- Local power structures: Understand both formal government structures and informal power dynamics within communities.

- Infrastructure variations: Assess the reliability of power, transportation, and communication networks.

- Natural disaster risk: Evaluate exposure to regional weather patterns and geological risks.

- Labor dynamics: Learn workforce availability, skill levels, and labor relations specific to each area.

- Security forces: Gauge the capability and reliability of local law enforcement and private security options.

Manufacturing Proximity Shift

The new US administration’s push toward nearshoring has created an entirely new set of challenges. While proximity to the US offers obvious advantages, companies need to resist the urge to rush in without proper due diligence. We’re seeing organizations learn the hard way that closer doesn’t automatically mean easier or safer.

Companies moving from China to Mexico or other LATAM countries often prepare for obvious operational risks but underestimate the sophisticated nature of organized crime and other risks in the region. They’re discovering that moving closer to the US does simplify some supply chain concerns but creates other problems that they had not prepared for.

Last-Mile Vulnerability

Companies often discover they have a security blind spot in the final mile of delivery. You can have world-class security protocols at your manufacturing facilities, sophisticated tracking systems, and vetted transportation partners. Still, that last stretch of delivery (whether for raw materials or components to a factory or to the consumer) often proves to be the weakest link in the security chain.

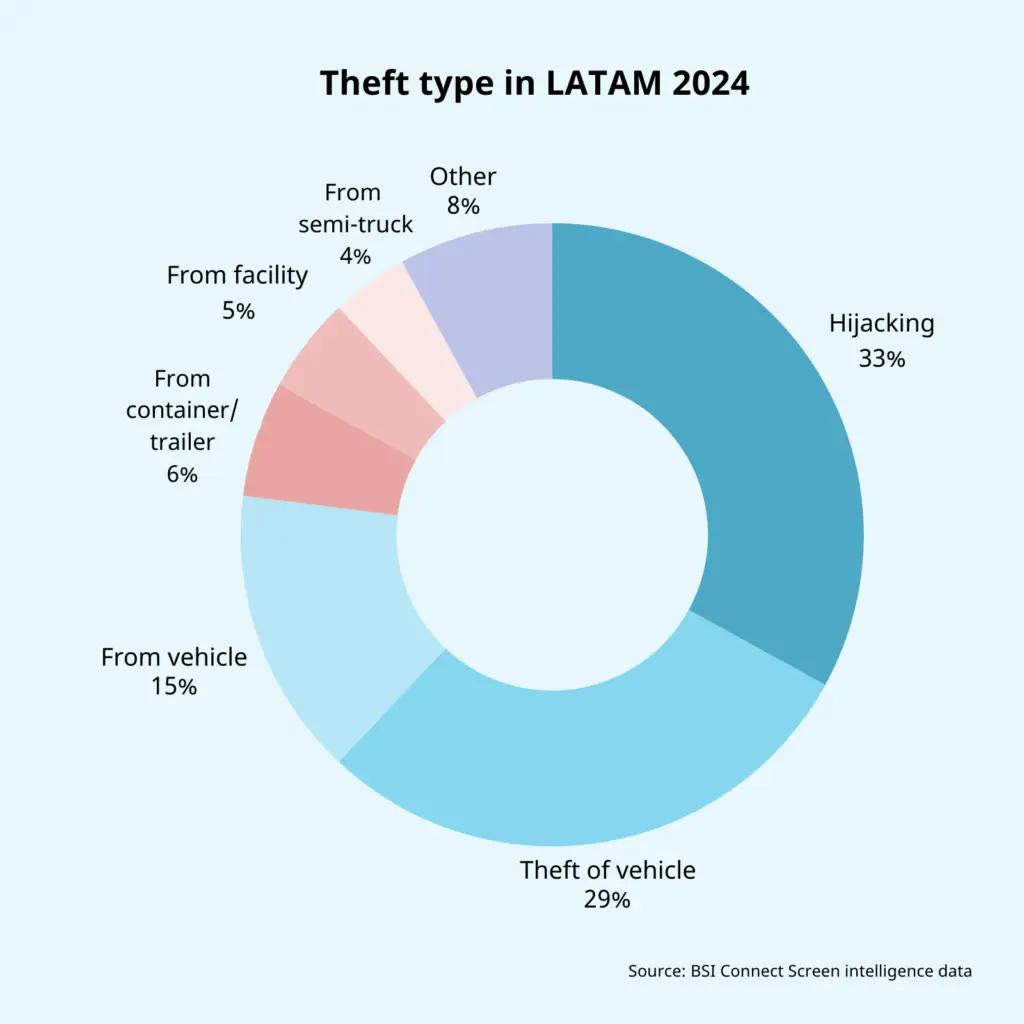

The phenomenon known as “last-mile vulnerability” has become increasingly prevalent across LATAM, where sophisticated criminal organizations have learned to identify and exploit these delivery weak points. We’ve seen cases where organizations invested millions in facility security and route optimization only to experience significant losses during that crucial final delivery phase. It’s like having a state-of-the-art safe with an unlocked door.

A critical yet often overlooked part of supply chain security is the danger of complacency. Even companies with decades of regional experience can find themselves vulnerable to risks that have evolved gradually but significantly over time or changes to the business that have exposed them to new and previously unknown risks. What was once an effective security protocol may now have critical gaps, particularly as criminal organizations become more sophisticated. Security strategies require regular reassessment and a holistic approach that integrates an organization’s operations, logistics, customs, and security perspectives.

Standard operating procedures (SOPs) should be living documents, frequently updated to reflect emerging threats and changing regulatory requirements. The most successful organizations embrace enterprise security risk management as a process, not a static set of protocols.

Why BSI and AFIMAC?

AFIMAC Global, the standard-bearer for business labor continuity, and BSI Group, global experts in business improvement and standards development, have partnered to help organizations across different industries:

- Better anticipate, understand, and manage supply chain risks and opportunities

- Navigate a varied and complex regulatory landscape

- Address critical security and operational resilience challenges

By combining BSI’s expertise in supply chain intelligence, regulatory compliance, and digital trust with AFIMAC’s business labor continuity and risk management capabilities, the alliance aims to offer a comprehensive suite of solutions tailored to meet organizations’ evolving needs around security, supply chain, and resilience.